In the food processing industry, maintaining product safety is essential. Metal contamination can pose serious risks to consumers and damage a brand’s reputation. That’s why using a food metal detector is standard practice across production lines. However, the accuracy and performance of these systems can vary depending on several key factors. Understanding these influences can help optimize detection reliability and reduce the risk of undetected contaminants.

Product Effect and Composition

One of the most significant factors affecting metal detection is the product itself. Items with high moisture or salt content, such as bread, cheese, or processed meats, can create a “product effect.” This occurs when the product generates its own signal, which may interfere with the food metal detector‘s ability to distinguish between the product and actual metal contaminants. Adjusting settings or using phase tracking technology can help minimize this interference.

Packaging Materials

Packaging plays a major role in detection performance. Products packaged in metallic foil or film can make it difficult for traditional metal detectors to identify contaminants. In these cases, the orientation of the product and the type of metal detector used become crucial. While some detectors are designed to handle such packaging, others may require alternative inspection methods like X-ray systems.

Environmental Conditions

External factors such as temperature, humidity, and vibration can also influence detector sensitivity. For example, cold or frozen products may behave differently in the detection zone than room-temperature items. Additionally, high humidity can cause condensation, which may affect the detector’s readings. Regular calibration and environmental control are essential for maintaining consistent performance.

Equipment Maintenance and Calibration

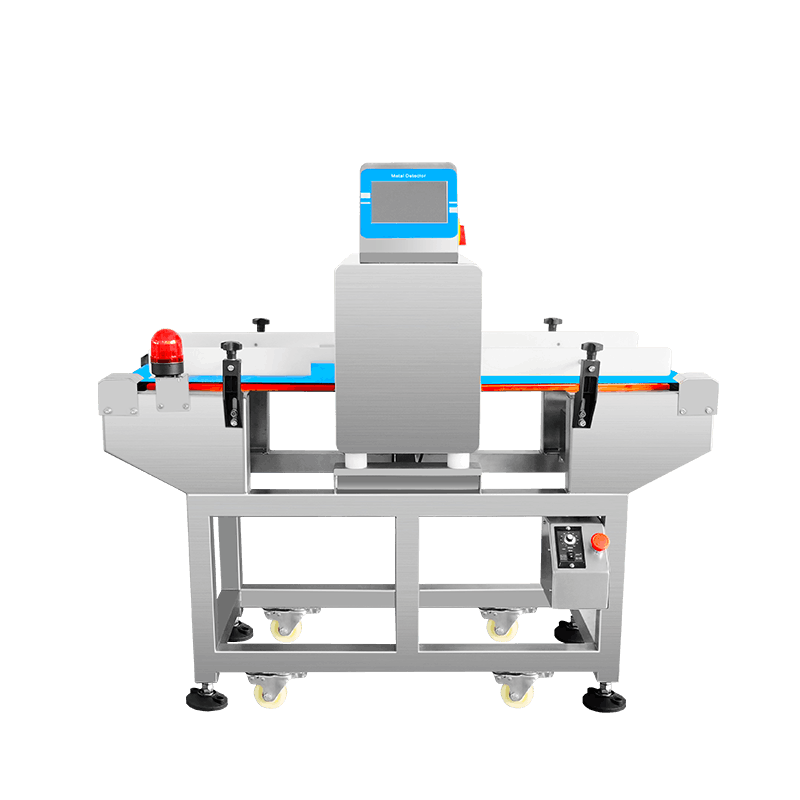

Like any precision equipment, metal detectors require regular maintenance and calibration. Dirty sensors, worn belts, or outdated software can lead to inaccurate results or false rejects. Scheduling routine inspections ensures that the food metal detector operates at peak performance.

Optimizing Metal Detection for Safer Production

Achieving accurate metal detection in food processing depends on multiple factors—from the nature of the product to environmental conditions. By understanding these variables, manufacturers can improve inspection accuracy and reduce contamination risks. Foodman provides support and technology that help food producers maintain high standards of safety and compliance with every batch.