The rising demand for electric vehicles and renewable energy sources has significantly increased the need for efficient battery manufacturing equipment. Companies looking to establish a lithium battery assembly line often grapple with the crucial question of cost. Not only does this investment involve machinery and equipment, but it also encompasses aspects such as labor, space, and ongoing maintenance.

Initial Investment in Machinery

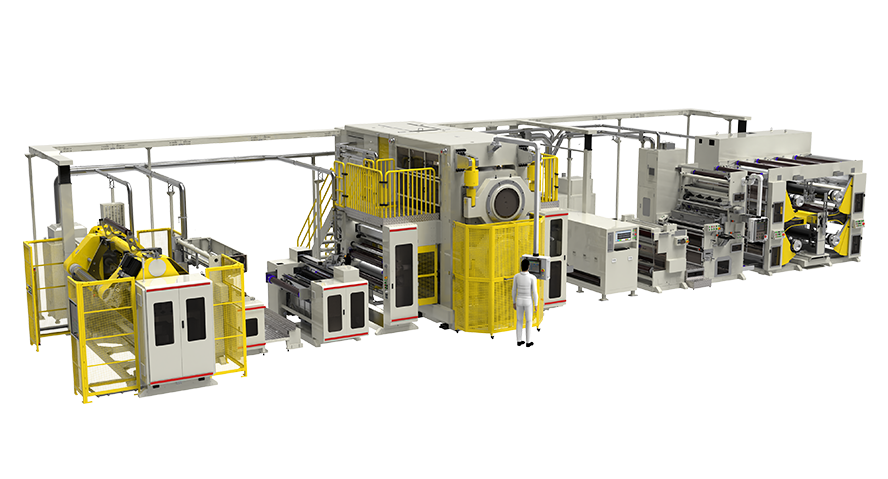

Establishing an EV battery production line requires substantial capital investment, especially in high-quality machinery. One of the most noteworthy pieces of equipment is the Calendering and Slitting Integrated Machine. This advanced machine offers automatic rewinding and unwinding capabilities and employs cutting-edge high-speed online roller cleaning technology. With a production speed of up to 120m/min and a maximum roller width of 1500mm, companies can optimize their battery manufacturing process. Depending on specific configurations and additional features, the cost of such machinery can range from hundreds of thousands to several million dollars.

Operational Costs

Beyond the initial capital expenditure on machinery, businesses must consider operational costs, including labor, utilities, and maintenance. Skilled technicians are essential for overseeing the assembly line, ensuring that the battery manufacturing process runs smoothly and efficiently. These qualified professionals can contribute significantly to the operational budget. Additionally, regular maintenance of sophisticated machinery like the Calendering and Slitting Integrated Machine is crucial for sustaining production efficiency and minimizing downtime.

Future-Proofing Investments

As the market for battery manufacturing continues to evolve, investing in state-of-the-art machinery and technology becomes increasingly vital. Companies should carefully evaluate suppliers like Yinghe, known for high-performance battery assembly solutions. By choosing reliable brands, manufacturers can secure equipment designed for longevity, enhancing the overall return on investment.

In summary, while the upfront costs of setting up a lithium battery assembly line may seem daunting, strategic investments in high-quality machinery and skilled labor can yield significant long-term benefits in a burgeoning market.