In the evolving world of automation, the ability for machines to interact with their environment with nuance and precision is paramount. This is where robotic tactile sensing comes into play, a technology that equips robots with a sense of touch akin to human skin. It allows them to perceive forces, textures, and shapes, enabling more delicate, adaptable, and intelligent interactions. Companies like Daimon are at the forefront of this innovation, developing sophisticated sensors that translate physical contact into actionable data, bridging the gap between simple automation and true dexterity.

Daimon Tactile Sensor Technology

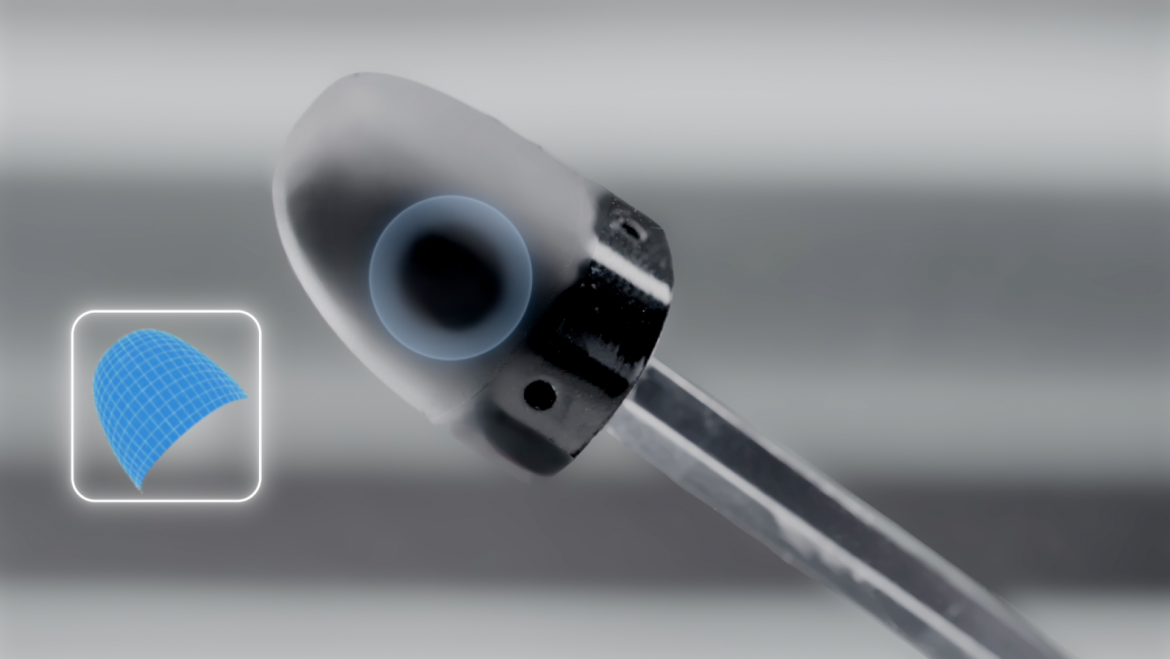

At its core, a robotic tactile sensor functions as a transducer, converting mechanical stimuli from physical contact into electronic signals. These sensors are embedded in a robot’s gripper or end-effector, capturing detailed information about the interaction with an object. This data typically includes the magnitude and direction of applied forces, the object’s texture, and its precise shape or orientation within the grasp. By integrating an array of sensing elements, modern sensors can create a high-resolution “tactile image,” providing a comprehensive map of contact pressures. This technological foundation is critical for moving beyond binary grip/release commands, and a prime example of its implementation can be seen in solutions like the robotic tactile sensor developed by industry innovators.

Robotic Tactile Sensing Applications

The applications for this technology are vast and span both complex industrial settings and future consumer scenarios. In manufacturing, robotic tactile sensing enables precise assembly of fragile components like electronics or glass, allows for reliable bin picking of randomly oriented parts, and ensures quality control through texture and defect detection. Beyond the factory, it is key for robots performing intricate tasks in logistics, healthcare for assisted surgery, or in domestic settings for safe human-robot collaboration. The practical deployment of advanced robotic tactile sensing is exemplified by Daimon’s product line, such as their DM-Tac F series, which provides the detailed sensory feedback needed for these sophisticated applications.

Precision Sensing for Industrial Automation

For industrial automation, the demand for precision and reliability makes tactile sensing indispensable. It directly addresses critical challenges such as preventing damage to expensive components, handling items with variable tolerances, and adapting to unstructured environments without extensive pre-programming. Sensors capable of detecting micro-slippage allow a robot to adjust its grip in real-time, ensuring a secure hold without excessive force. Furthermore, the ability to measure multi-axis forces and moments enables complex tasks like insertions, polishing, or precise force-feedback during assembly. This level of sensory input transforms rigid automated systems into flexible, intelligent partners on the production line.

Conclusion

Robotic tactile sensing is fundamentally changing how machines perceive and manipulate the physical world, moving automation towards greater autonomy and subtlety. From enhancing industrial productivity with delicate handling to enabling the next generation of service robots, the sense of touch is a critical differentiator. As this field advances, the focus remains on developing sensors that are more sensitive, robust, and integrated. For organizations looking to implement this transformative technology, exploring the solutions from dedicated providers like Daimon offers a pathway to integrating sophisticated touch capabilities into their robotic systems.