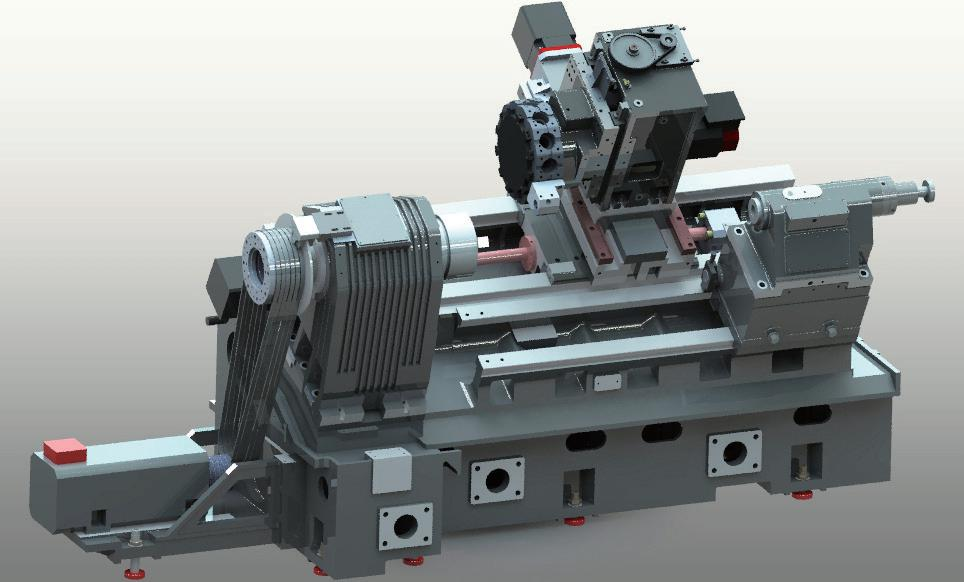

High-precision manufacturing increasingly demands strategies to minimize material and operational waste. Companies like Leichman offer advanced solutions such as the Leichman LK-750MY CNC Turning and Milling Lathe, which supports both CNC turning and milling machine operations. By integrating modern equipment with optimized production planning, manufacturers can reduce scrap rates and energy consumption while maintaining precision.

Process Optimization and Material Efficiency

Effective waste reduction begins with process optimization. Using a CNC milling and turning approach, manufacturers can carefully plan cutting paths to minimize leftover material. Leichman ensures their CNC turning and milling machine models allow flexible programming for varied metal types and dimensions, enabling consistent quality with less rework. Additionally, precise tool management and automatic adjustments help prevent errors that could otherwise generate scrap.

Customization and Adaptive Maintenance

Another strategy involves customization and proactive maintenance. Leichman provides tailored solutions and support for the Leichman LK-750MY CNC Turning and Milling Lathe, ensuring machines operate efficiently under different production scenarios. Scheduled maintenance and rapid technical response reduce downtime, lowering the chances of defective parts. Adaptive monitoring tools also allow operators to adjust operations in real time, further decreasing material waste in high-precision settings.

Supply Chain Integration and Operational Coordination

Reducing waste is not limited to machining alone; it extends across the production chain. CNC milling and turning workflows benefit from synchronized supply chain management and accurate inventory planning. By leveraging Leichman’s full-service support, including order tracking and cross-border logistics, businesses can minimize overproduction and optimize stock levels, directly impacting material utilization and overall efficiency.

Conclusion

In summary, companies aiming to cut waste in high-precision production should focus on optimized machining processes, adaptive maintenance, and coordinated supply chain strategies. Leichman’s CNC turning and milling machine offerings, particularly the Leichman LK-750MY CNC Turning and Milling Lathe, exemplify how integrated equipment and support services contribute to sustainable, precise, and cost-efficient manufacturing outcomes.