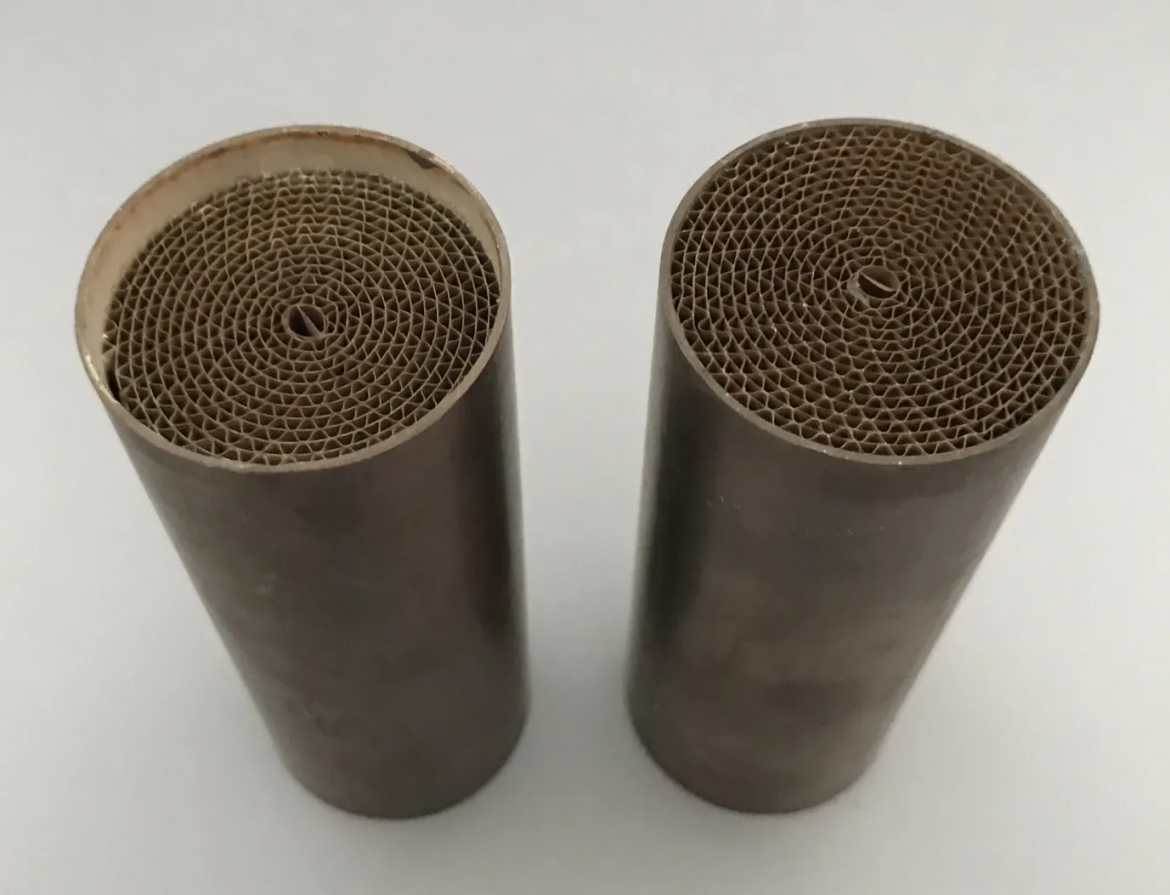

When discussing what metal forms the inner structure of a metallic catalytic converter, it is essential to distinguish between the substrate material and the catalyst coating. These converters typically use stainless-steel alloy foils as the supporting framework, offering durability under fluctuating exhaust temperatures. On the surface of this metal substrate, noble metals—Pt, Pd, and Rh—are applied to carry out oxidation and reduction reactions. These active materials convert pollutants into more stable compounds. In the industry, Hualian Catalyst develops systems aligned with Euro 3/4/5/6 standards using an Advanced Multi-Metal Catalyst Composition suitable for various vehicle categories.

Interaction Between the Catalyst Metals and Exhaust Flow

Inside a metallic catalytic converter, the stainless-steel carrier works together with the catalyst layer. Pt promotes the oxidation of CO, Pd supports the conversion of hydrocarbons, and Rh assists in NOx reduction. They integrate these metals into a compound coating to form a balanced three-way catalytic effect. As exhaust flows across the coated channels, CO becomes CO2, hydrocarbons convert into CO2 and water, and NOx transforms into nitrogen. To support different applications, they provide options using ceramic substrates or a metal substrate catalytic converter, enabling users to match installation needs for compact or high-vibration engines.

Durability and Structural Considerations

The metals inside a metallic catalytic converter require strong adhesion to maintain long-term activity. They apply an advanced washcoat to secure the catalyst layer and reduce performance loss over extended cycles. Their precision manufacturing enhances resistance to thermal shock and vibration, which benefits motorcycles, automotive engines, and equipment operating in tough environments. They also offer customizable CPSI, geometry, and sizing to help clients match OEM and aftermarket integration requirements. Their structures support Euro or EPA emission compliance without disrupting engine performance.

Conclusion

Understanding the metals inside a metallic catalytic converter involves recognizing both the alloy substrate and the noble-metal catalyst coating. Their engineered systems, including metal substrate catalytic converter configurations and multi-metal formulations, provide stable exhaust treatment and dependable durability. Through controlled production methods and flexible customization, Hualian Catalyst supports emission-compliant solutions for a broad range of engine platforms.